- Home

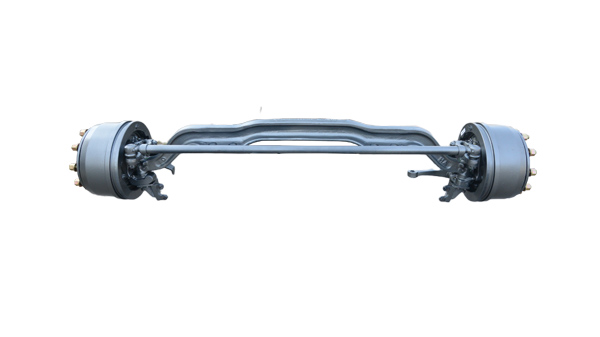

- I-Beam Axle

- Truck Axle & Seat

9 ton truck steering axle7.5 ton truck steering axle6.5 ton truck steering axle5.5 ton truck steering axle5 ton truck steering axle4 ton truck steering axle3.5 ton truck steering axle3 ton truck steering axle2 ton truck steering axle1.5 ton truck steering axle1 ton truck steering axleSteering tie-rodSteering drag linkMaintenance-free tie rodDeep drop tie-rod endsBottom r-arc u-boltBottom flat u-boltBottom half round U-boltForged flat U-bolt

- Welded Structural Parts

Welded structural parts of lifting machine chassisWelded structural parts of lifting machine platformWelded structural parts of lifting machine scissorsOther welded structural parts of lifting machineWelded structural parts for chassis of road sweeperWelded structural parts of garbage truckWelded structural parts of cotton picker chassiWelded structural parts of corn harvester chassisWelded structural parts of wheat harvester chassis

- News

- Cases

- About Us